Ultrasonic Testing, Magnetic-particle Testing, Liquid penetrant Testing, Radiographic Testing, Visual Testing, Advance Ultrasonic Testing, Tube inspection

Heat exchangers used for petrochemical or power generation applications may have many thousands of tubes, each up to 20 m long. UIC Services provides a comprehensive inspection program consisting of multiple..

It is one of the most common a non-destructive testing (NDT) method where sound waves of high frequency(ranges from 1 MHZ TO 50MHZ) waves are transmitted into the material being tested are used to detect surface and sub-surface flaws.

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys.

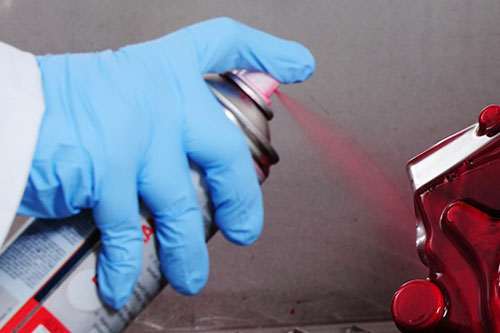

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials..

Industrial radiography is a method of non-destructive testing where many types of manufactured components can be examined to verify the internal structure and integrity of the specimen. Industrial Radiography can be performed utilizing either X-rays or gamma rays.

Visual inspection is one of the most common and most powerful means of non-destructive testing. Visual testing requires adequate illumination of the test surface and proper eye-sight of the tester. To be most effective visual inspection does however, merit special attention..

UIC is a leader in the Ultrasonic Testing and Training industry. Experience, high skill levels and state of the art equipment keep us ready to handle any inspection applications. UIC can support your company with all your advanced ultrasonic needs with tools such as TOFD..

Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.[1] The terms Nondestructive examination (NDE), Nondestructive inspection (NDI), and Nondestructive evaluation (NDE) are also commonly used to describe this technology.[2] Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. Common NDT methods include ultrasonic, magnetic-particle, liquid penetrant, radiographic, remote visual inspection (RVI), eddy-current testing,[1] and low coherence interferometry.[3][4] NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art.[1] Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

NDT is used in a variety of settings that covers a wide range of industrial activity, with new NDT methods and applications, being continuously developed. Non-destructive testing methods are routinely applied in industries where a failure of a component would cause significant hazard or economic loss, such as in transportation, pressure vessels, building structures, piping, and hoisting equipment.